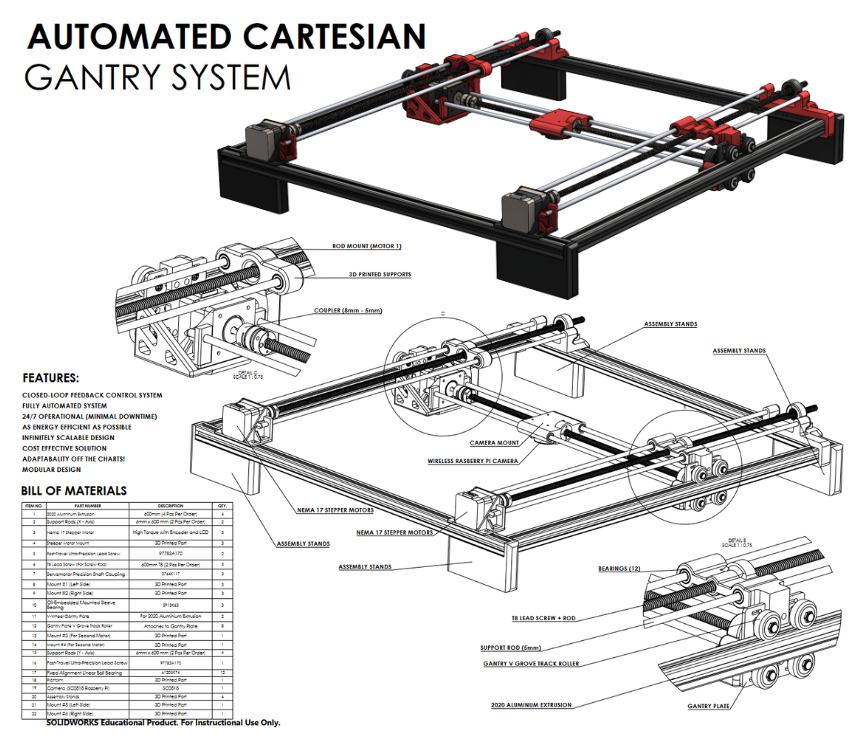

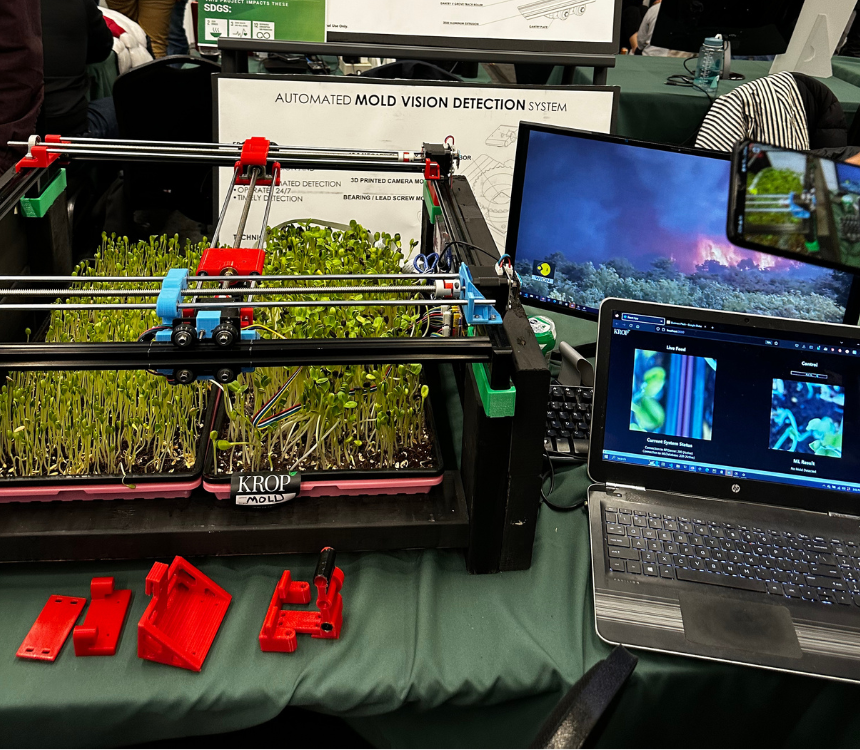

Cartesian Robot (2-Axis)

A deeper insight into the project...

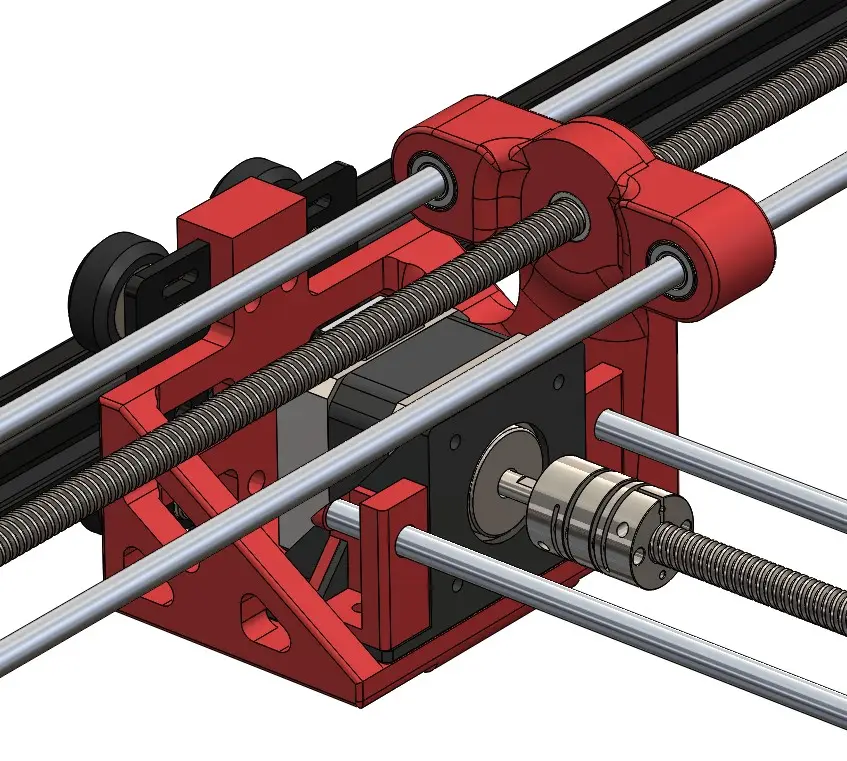

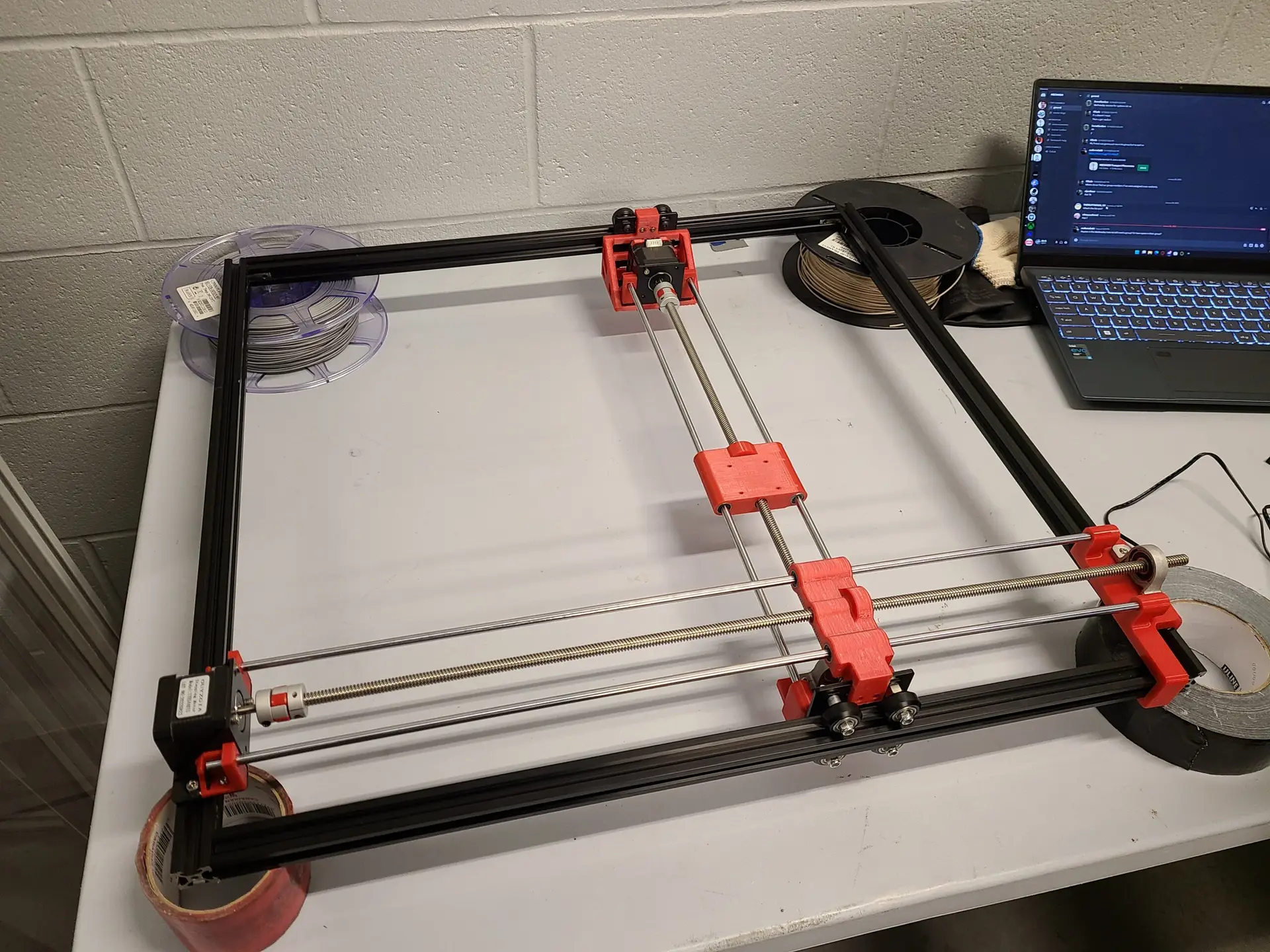

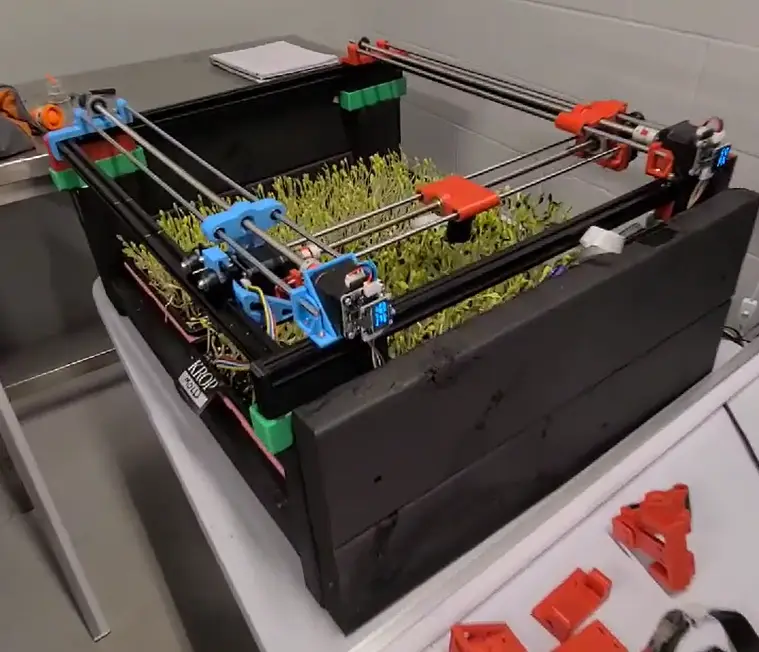

Developed a Cartesian Robot for Mold Mitigation in vertical farming, meticulously designed in SolidWorks and refined through multiple in-house 3D-printed iterations. The project began with a comprehensive design phase in SolidWorks, where I created detailed models and performed simulations to ensure the robot’s components would meet the stringent requirements of a vertical farming environment. I personally selected, sourced, and assembled all parts, focusing on creating an effective and durable robotic system capable of operating in agricultural settings.

To ensure reliable performance, the robot was controlled by a microcontroller and a custom PCB circuit, which I designed using Autodesk Eagle. This custom PCB integrated seamlessly with the robot’s electronic components, providing precise control and robust functionality. I programmed the microcontroller to manage the robot’s movements and responses, optimizing it for mold mitigation tasks. Additionally, I conducted extensive testing and troubleshooting to fine-tune the system, ensuring it could handle the unique challenges of vertical farming, such as limited space and varying humidity levels. The end result was a highly effective Cartesian robot that significantly improved mold mitigation processes, contributing to healthier crop yields and more efficient farming operations.