CNC Build: Spindle Sizing (Part Two)

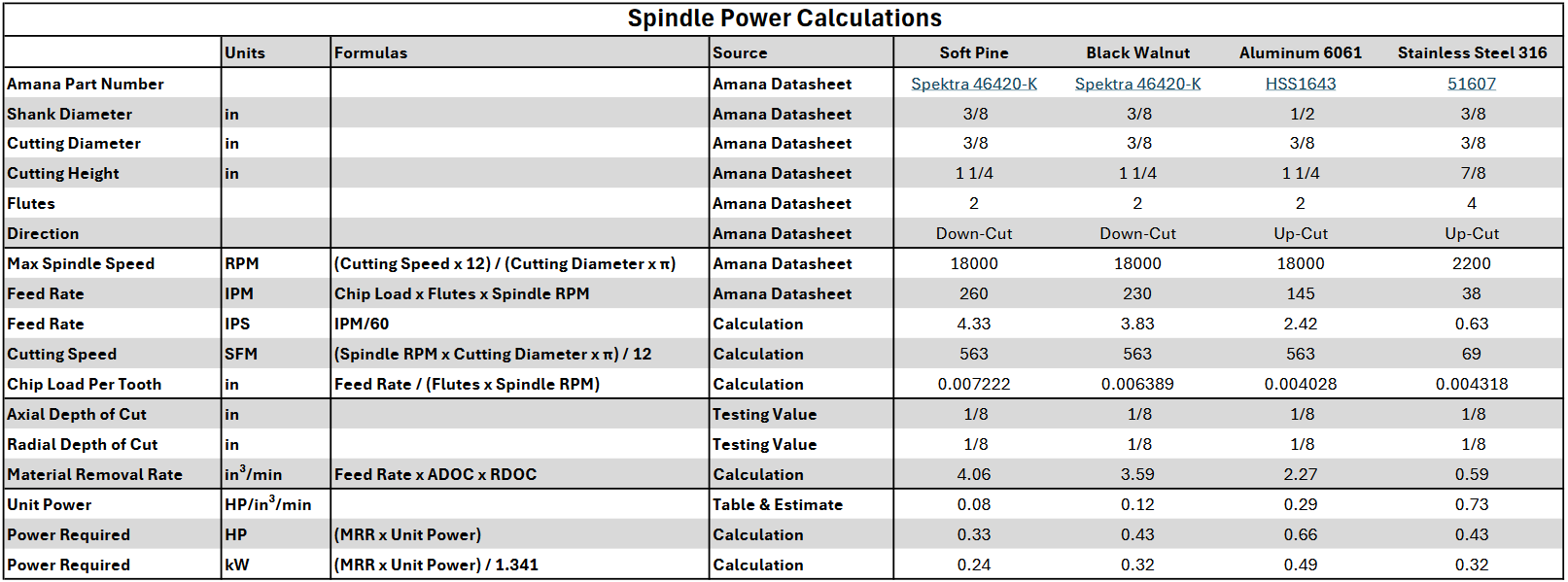

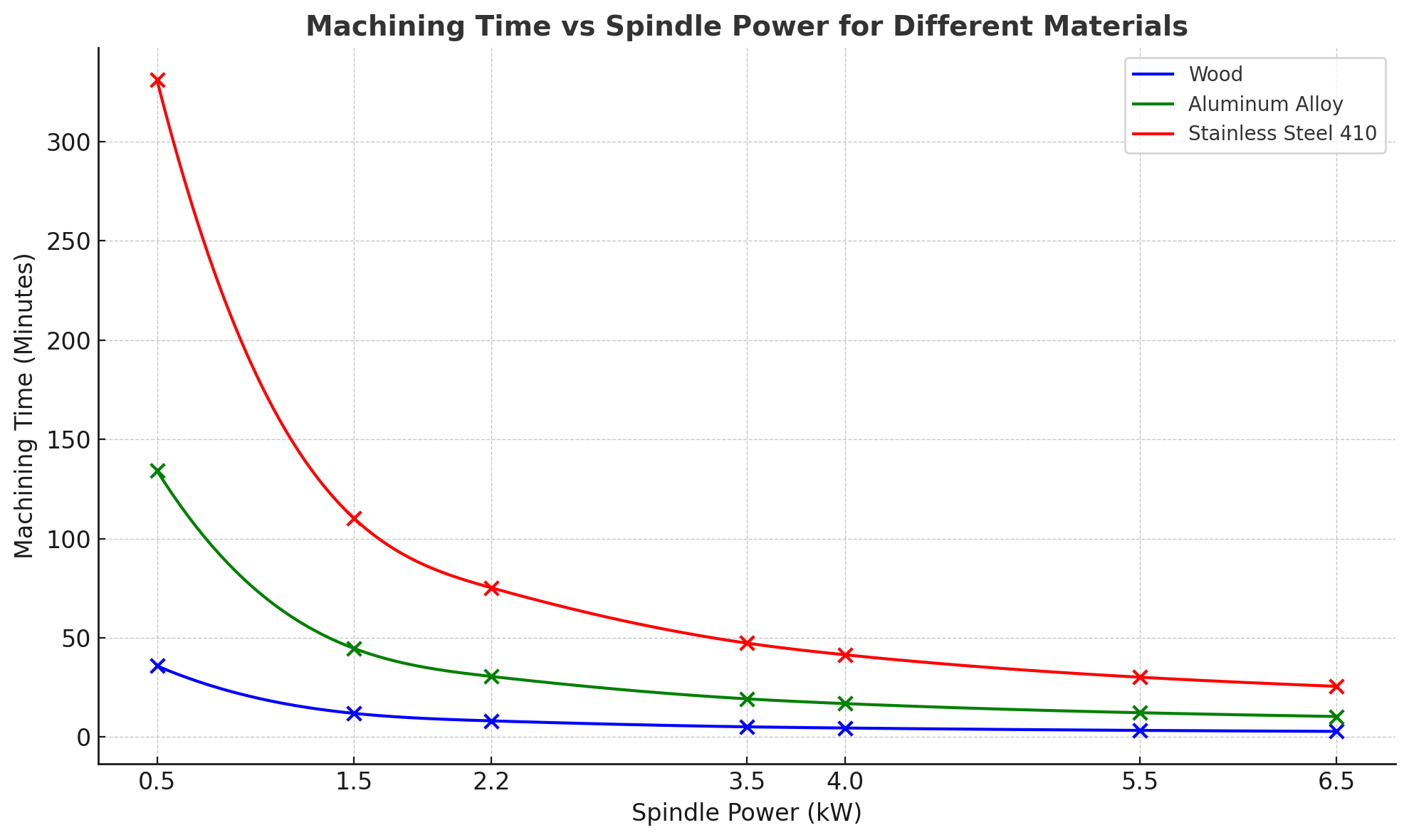

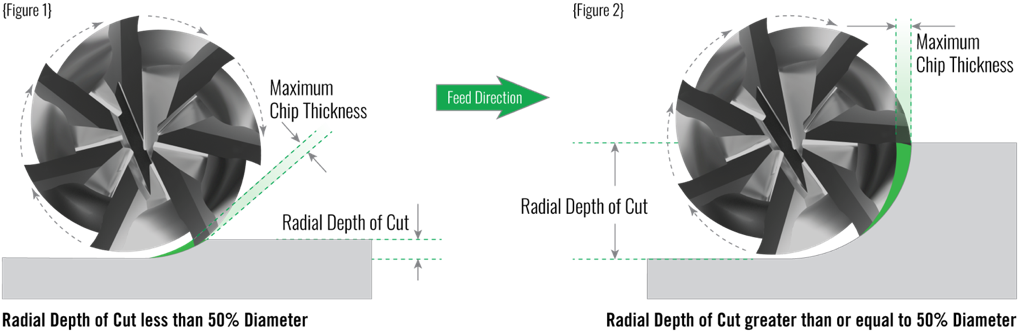

This article delves into the spindle size selection process for my CNC build, with a focus on optimizing material removal rates and balancing spindle power requirements. Through heatmaps and detailed analysis of Axial and Radial Depth of Cut, the study concludes that a 2.2 kW spindle strikes the best balance between power, efficiency, and flexibility for most CNC operations.